A consensus has been arrived at the global level that we may have to essentially reduce greenhouse gas emissions and foster a sustainable low-carbon economy for our own survival.

Humanity, in today’s world, is facing the dual challenge of rising energy demand propelled by economic growth and the necessity of countering the environmental consequences of carbon emissions into the atmosphere, in line with the Paris Agreement. International Energy Agency (IEA) predicts that the global energy consumption will double by 2050. Intergovernmental Panel on Climate Change (IPCC) and its Conference of the Parties (COP) mandates that global anthropogenic emissions be reduced and achieve a state of net-zero emissions by 2050 to prevent an impending climatic disaster. Greenhouse gases, especially carbon dioxide, emitted from human engagements using fossil fuel and feedstock, currently and over the years, significantly contribute to warming of the atmosphere which results in climatic distortions that started impairing human settlements and threaten life on earth at alarming proportions. Therefore, a consensus has been arrived at the global level that we may have to essentially reduce greenhouse gas emissions and foster a sustainable low carbon economy for our own survival.

How to achieve these two mutually contradicting goals and take human development forward is being widely debated among national governments, policy planners, technology developers, business, and industry. Several international institutions, corporates, networks, and NGOs are working together with the UN taking a lead to develop a sustainable development paradigm for the future world.

Fortunately, in the past over three decades, several advancements in the realm of science, technology and management have paved the way for a host of eco-friendly innovations to curb emissions from carbon intensive human activities. It includes renewable energy sources, improvement in energy efficiency and operational reliability and waste reduction techniques. While renewable energy sources like solar and wind power have no emission inventory attached to it, several other technologies significantly reduce greenhouse gas emissions and help to move away from conventional fossil fuels.

Research and industry have identified hydrogen to play a significant role in the transition from carbonaceous fuels to clean energy resources without CO2 emissions. Hydrogen the lightest gas and the first element in the periodic table of elements is regarded as the long-term sustainable option as the future energy source. Unlike hydrocarbons, all of which are fossil origin and barring a few synthetic fuels, hydrogen, up on combustion produces only water and no carbon dioxide or other greenhouse gases. Hydrogen, plentifully available in nature, but only in the combined form needs the intervention of high order energy transactions for its liberation to the free molecular form. Hitherto, most manufacturing processes involving hydrogen— ammonia, methanol, and other chemicals—used the energy of fossil fuels for its separation and downstream uses which invariably resulted in the emission of large quantum of CO2. Around 90 per cent of the hydrogen produced today is either through the steam methane reforming (SMR), auto-thermal reforming (ATR) or Gasification process using methane, naphtha, fuel oil, petroleum coke or coal—all of fossil origin.

Colours of hydrogen

In the energy industry, different colours are attributed to hydrogen depending on its carbon intensity—a measure of emissions given out during production. Well known processes like steam methane reforming or partial oxidation of hydrocarbon feedstock like oil or natural gas produce grey hydrogen along with emissions of greenhouse gases predominantly carbon dioxide. If the carbon dioxide emitted is subsequently contained through a process called carbon sequestration—sending the compressed gas to abandoned oil wells or other mines beneath the earth, so that it will not to rise again and cause warming up of the atmosphere and consequent climatic distortions-- the hydrogen so produced is termed as blue hydrogen. Green hydrogen is the gas so produced from electrolysis of water using renewable (green) electricity without any emissions throughout its entire life-cycle from production to end use. Globally, green hydrogen is considered as a critical component of decarbonising manufacturing sectors, besides being an alternative fuel and feedstock.

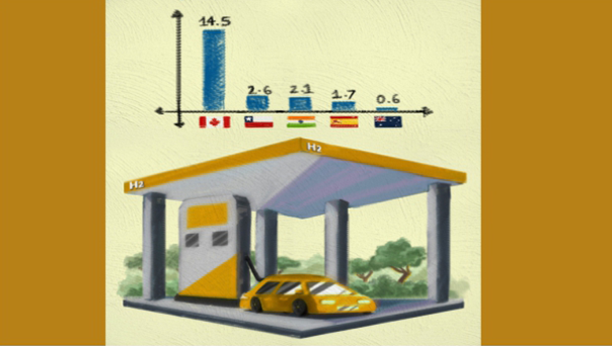

Several countries including India have plans to build hydrogen hubs which include renewable energy production, electrolysers for producing green hydrogen from water, storages, pipelines, tanks, and other logistics infrastructure, refueling stations and fuel cells for converting it into electricity or hydrogen IC engines. Critical challenges in the development of green hydrogen technologies include development of cost effective and efficient electrolysers and building the necessary infrastructure for handling, storage, and dispensation of hydrogen. The Green Hydrogen Catapult (GHC), a global initiative organised with the support of the UN High Level Champions for Global Climate Action and a coalition of industry leaders in developing the clean fuel, formed in 2020, commits to commission electrolysers from 25 GW to 45 GW by 2027. The coalition says the effort will keep the price below US$2 per kilogram of green hydrogen, which will allow the clean fuel to be cost effective in the short term.

According to McKinsey, hydrogen combustion is a nascent solution but could fill an important niche by harnessing established technologies and supply chains. Among the four zero-emissions technologies—batteries, fuel-cells, hydrogen IC engines and biofuel or synfuel IC engines—hydrogen combustion is still in its infancy, despite a history going back to the 1806 de Rivaz engine, which ran on a hydrogen–oxygen mixture. For a long time, hydrogen combustion engines were disregarded, as the very high costs of hydrogen made the power train uneconomical. Today, however, some automotive OEMs, component suppliers, and start-ups are reconsidering hydrogen combustion as an additional component of their future power train portfolios, alongside batteries and fuel cells.

Renewable power technologies especially solar and wind have become proven both in efficiency and scale on account of which generation is increasing and cost per unit power is declining year to year. The ongoing research and innovation in other sectors— biomass, geothermal and tidal—is likely to witness attainment of technical maturity and economic viability in the coming decades. There is also a renewed thinking on nuclear power which is also carbon neutral, but has serious safety and environmental considerations to comply with and much depends on national policies and shifting approaches to technologies.

Electrolysers

The equipment used for splitting water into its elements using electricity is called electrolysers. Water electrolysers are divided into four different types based on the nature of the electrolyte used and the operating temperature. It includes the alkaline water electrolyser, polymer electrolyte membrane water electrolyser (PEM), anion exchange membrane water electrolyser (AEM) and the Solid oxide electrolyte water electrolyser (SOE). Alkaline and PEM electrolysers are mature technologies and are already commercialised, while AEM and SOE are in their early development and near[1]commercialisation stage.

Major uses of green hydrogen include power generation, steel making, production of cement, manufacturing ammonia for the fertilizer industry and as an energy source to power heavy industry and fuel large vehicles including aircraft and ships. Producers and technology providers are jointly assessing the feasibility of low carbon economic capacity plants in the global fertiliser, chemical, steel, cement, energy, and shipping industries.

Power

According to BP Statistical Review of World Energy 2022, of the 28,466 terawatts of electricity produced in 2020, 17,483 terawatt (61 per cent) is generated out of fossil fuels— coal, oil, and natural gas. The IPCC estimates that production of electricity emits 10 giga tons, or approximately 37 per cent of global CO2 emissions. Therefore, renewable power generation becomes a priority agenda of producers supplying power to the grid. In the transport sector also, green hydrogen is set to replace fossil fuels.

Steel

Production of steel is estimated to contribute to about 9 per cent of carbon dioxide emissions globally and therefore, a higher carbon footprint due to the burning of fossil fuels. Experimentation is underway to produce direct reduced iron (DRI) from iron ore using green hydrogen instead of natural gas. According to McKinsey, hydrogen-based DRI is, therefore, expected to be a major decarbonisation lever for steel makers, and several companies have already announced plans to introduce DRI, and strong growth is expected in the future. In fact, scenarios based on a carbon-neutral steel industry—a goal many major steelmakers have pledged—have DRI production tripling within the next 30 years.

Ammonia

In 2022 world ammonia production stood at 190 million tons (FAO, 2022) with China, Russia, India, and the US as the major players. Around 80 per cent of synthetic ammonia is used for making mineral fertilisers for enhancing crops yields. Other user industries include plastics, fibers, explosives, nitric acid, and intermediates. In the future ammonia is expected to be useful as an energy storage, zero carbon fuel and a hydrogen carrier for long distance hauling of ocean vessels etc. The International Fertilizer Industry Association (IFA) estimates that approximately 2 per cent of the world’s energy is used for fertilizer production of which, 93 per cent is marked for ammonia. Despite the enormous strides made by the industry in bygone years in reducing emissions, current ammonia production methods still contribute to 1.3 per cent of total global emissions in 2022 (IFA, 2022). It is generally agreed in the industry that a further reduction in energy consumption of the order of 6 to 7 per cent is possible even in the most efficiently operating plants, although this would come through with an increased capex.

Cement

In 2022 the global cement production was 4.1 billion tons. The emissions from the cement industry arises out of its use of fossil fuels for processing and from the use of limestone as a raw material. It accounts for over 7 per cent of total global CO2 emissions, i.e., for every ton of cement produced it emits 0.6 ton of CO2. Green Hydrogen can be used as a fuel in the cement production process to replace fossil fuels such as coal, coke, and natural gas. The production of clinker, an intermediate in cement production, is responsible for a substantial amount of CO2 emissions and hydrogen can be used to reduce the amount of clinker needed in cement production, as it can be used as a reducing agent in the raw material mix. This can reduce CO2 emissions from cement production by up to 50 per cent.

Indian efforts

India established a clear leadership in the decarbonisation by setting up of the National Hydrogen Mission in 2021 and through its targeted efforts to decarbonise each of the economic sectors. At the recently held G20 meeting in New Delhi, India proposed to establish a Green Hydrogen Innovation Centre and the Global Biofuel Alliance within its borders for facilitating technology sharing, capacity building, and sustainable investments in renewable energy projects. Still the bulk of the energy production in India comes from coal which is the most emission intensive input for power generation. Being the abode of a large section of young people- nearly 70% of the country’s population- our development aspirations cannot be put on hold instantly and thus the use of coal as a fuel and feedstock cannot be done away. Instead, the government envisages a gradual transition to greener options for power generation to decarbonise the grid. A great deal of investments both from the public and private sector will be necessary to make the grid carbon neutral. Here a well laid out pathway for decarbonisation at the national level duly supported by clearly defined policy prescriptions are required to facilitate private investment in this area. Government of India’s recent notification of Green Hydrogen Standard which specify the emission thresholds during production, is a right step forward in this direction especially at a time when globally acceptable standards in this respect are lacking.

India’s NITI Aayog reports that the cost of hydrogen production through electrolysis ranges from $4.10-$7 per kg based on the technology used and including operating costs, transmission and distribution costs, wheeling costs for electricity and the local duties and taxes as against $2 per kg through the SMR route for grey hydrogen. Therefore, the cost of the electrolysers may have to be brought down to produce hydrogen at competitive rates. Globally most green hydrogen technology providers are innovating their designs of electrolysers. India also needs to catch up with these developments with our engineering expertise and through R&D institutions and get recognized as an international market player in the segment. The burgeoning global green hydrogen market is projected to be worth $11 trillion by 2050, as per Goldman Sachs’ estimates. This very well auger with the recent report by NASSCOM and BCG which predicted that India’s Engineering Research and Development (ER&D) sector is set to increase its contribution to the global ER&D sourcing market which currently is at 17 per cent and valued at $44-45 billion is expected to grow to 22 per cent and $130-170 billion by 2030.

Unlike in the past, about technological advances in several sectors, the approach taken by the Government of India towards fostering a hydrogen economy for the country was quick and timely.

The Prime Minister himself exhorted the importance to align with the ongoing technology developments in hydrogen sector as a sustainable alternative to fossil energy and the need to build inhouse expertise through active participation in research and innovation in this area. It is also recognized that Government support by way of viability gap funding etc. if needed for projects will come through. Even developed countries like the US are incentivising investments in green power and low carbon hydrogen infrastructure through enactments like the Inflation Reduction Act of 2022. Already the cost of renewable power generation in India is lower and it must come in handy for the country to reap the economic gains of the global energy transition. Government of India’s domestic manufacturing support under production linked incentive (PLI) scheme shall be extended to electrolyser manufacturing also.

Challenges ahead

In the prevailing market economy situation, it is difficult to expect that environmental sustainability and mitigation of climate change to prevail over corporate profitability. In such a case final investment decision of several of the 680 large scale green hydrogen projects proposed worldwide (May 2022) are likely to get delayed so that they may not be able to contribute to the planned decarbonisation targets in the coming years. The apprehension on the viability of green hydrogen vis a vis other fuels was raised in a recent study by the Barcelona based OBS Business School and also duly upheld by Mr Yuri Sebregts, Chief Technology Officer, Shell. This situation may be viewed in the context of the IPCC AR 6 report’s observation that global initiatives are not progressing well to meet the decarbonisation targets set for 2030 and the lack of commitment and clarity about Climate Funding assistance at COP 26 meeting. The disruption of the global agenda propelled by the onset of the Russia-Ukraine war and now the Hamas-Israel war is yet another hurdle. Thus, looking at the overall crisis from the technology, economics and geopolitical perspectives and taking stock of the progress achieved so far, one may like to conclude that the global decarbonisation effort is likely to lose momentum in the near term.

Log In or become an AIMA member to read more articles